Since 2021, Caligyr AG has continued to operate the E52 calibration center as an independent and autonomous subsidiary of Landis+Gyr AG. We stand for exact measurements, maximum transparency and absolute competitive neutrality - essential factors for precise and fair energy billing.

Whether energy supplier, network operator or industry - Caligyr AG is your reliable partner for precise and legally compliant verifications and calibrations.

Our strengths - your advantage

Technology & expertise

Based in Cham, Switzerland, we combine state-of-the-art measurement technology with in-depth expertise to meet the growing demands of energy supply.

Precision & compliance

Our metering solutions meet the highest legal standards, because correct metering values are the basis for trust and fairness in the energy market.

Certified neutrality

Officially recognized by METAS (2021), we guarantee impartiality, transparency and reliability for a fair and accurate calibration.

Our services

Sovereign tasks

As a competent and independent verification body, we take on a variety of sovereign tasks in accordance with legal requirements. These include

- Management of lots and inspections in the statistical inspection procedure

- Recalibrations to ensure measurement accuracy

- Diagnostic tests to clarify measurement deviations and complaints

Other activities

In addition to our sovereign tasks, we offer additional quality assurance services:

- Acceptance test to ensure measurement accuracy before commissioning

Our processes are precise, efficient and meet the highest quality standards - for a safe and reliable measurement infrastructure.

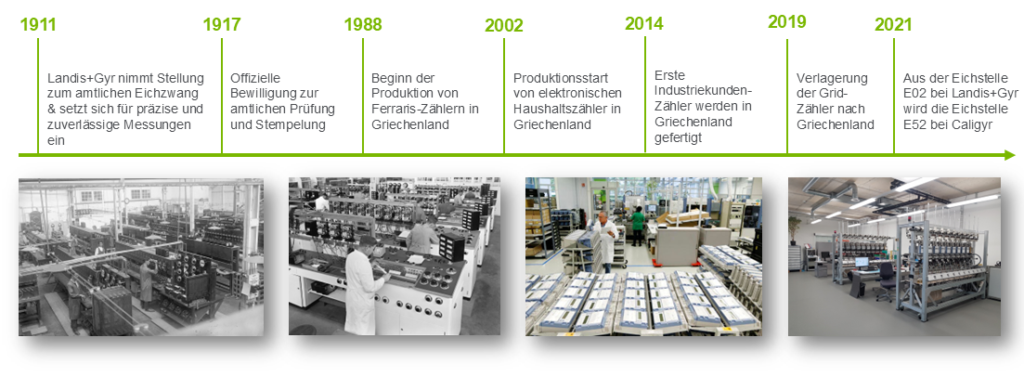

History of the calibration station

More about our work

Statistical test procedures

The Statistical test procedures, described in Annex 4 of the EMmVenables the metering accuracy of electricity meters to be checked efficiently without having to remove each individual meter. Instead, the check is carried out using a representative sample.

Procedure of the test procedure

Formation of a lot:

One lot comprises maximum 5000 meters of the same type and year of manufacture.

Several users may be represented together in one lot.

Every user has the right to know which other participants are in the same lot.

Inspection every five years:

A random sample is checked by a verification body authorized by METAS.

If the sample passes the test, the calibration validity of the entire batch is extended by five years.

If the sample does not meet the EMmV requirements, all meters in the batch must be replaced.

Registration for the test procedure:

Registration for participation must by the end of June of the fourth year after production of the meter at a calibration office.

This process ensures cost-efficient quality assurance without placing unnecessary strain on the entire measurement infrastructure. This ensures the accuracy and reliability of electricity measurement in the long term.

Acceptance test

Safety and precision for measuring devices

The quality of measuring devices is crucial for accurate billing, legal compliance and long-term reliability. With the introduction of the European Measuring Instruments Directive (MID) on 30 October 2006, the approval and calibration system in the EU member states was harmonized. However, the MID only regulates the placing on the market of measuring devices - to the sale, the national calibration law continues to apply.

Your responsibility as a measuring device user

While manufacturers are responsible for product quality, users of measuring devices also bear a significant responsibility for the accuracy of the measured values. Although the manufacturer's declaration of conformity can be relied upon, an additional quality acceptance test offers decisive advantages:

- Proof of product quality - you receive objective confirmation that the measuring devices meet the agreed standards.

- Higher acceptance probability for random sample inspections - verified quality reduces the risk of subsequent failures or deviations.

- Additional security for purchasers - A QAP ensures that the measuring devices supplied meet the technical and legal requirements.

Individual and customized quality inspection

The quality acceptance test is based on a clearly defined agreement between buyer and supplier. Both legal requirements and individual quality requirements are taken into account. This provides you with a customized inspection that is precisely tailored to your requirements.

Conclusion: A quality acceptance test protects against incorrect measured values, minimizes risks and ensures maximum transparency - an investment in safety and precision.