Seit 2021 führt die Caligyr AG die Eichstelle E52 als unabhängige und eigenständige Tochtergesellschaft der Landis+Gyr AG weiter. Wir stehen für exakte Messungen, maximale Transparenz und absolute Wettbewerbsneutralität – essenzielle Faktoren für eine präzise und faire Energieabrechnung.

Ob Energieversorger, Netzbetreiber oder Industrie – die Caligyr AG ist Ihr verlässlicher Partner für präzise und rechtskonforme Eichungen und Kalibrierungen.

Unsere Stärken – Ihr Vorteil

Technologie & Expertise

Mit Sitz in Cham, Schweiz, kombinieren wir modernste Messtechnik mit tiefgehender Expertise, um den wachsenden Anforderungen der Energieversorgung gerecht zu werden.

Präzision & Compliance

Unsere Messlösungen entsprechen den höchsten gesetzlichen Standards, denn korrekte Messwerte sind die Grundlage für Vertrauen und Fairness im Energiemarkt.

Zertifizierte Neutralität

Offiziell von METAS anerkannt (2021), garantieren wir Unparteilichkeit, Transparenz und Zuverlässigkeit für eine faire und genaue Kalibrierung.

Unsere Dienstleistungen

Hoheitliche Aufgaben

Als kompetente und unabhängige Eichstelle übernehmen wir eine Vielzahl hoheitlicher Aufgaben gemäss den gesetzlichen Vorgaben. Dazu gehören:

– Verwaltung von Losen und Prüfungen im statistischen Prüfverfahren

– Nacheichungen zur Sicherstellung der Messgenauigkeit

– Befundprüfungen zur Klärung von Messabweichungen und Reklamationen

Weitere Tätigkeiten

Neben unseren hoheitlichen Aufgaben bieten wir zusätzliche Dienstleistungen zur Qualitätssicherung:

– Annahmeprüfung zur Sicherstellung der Messgenauigkeit vor der Inbetriebnahme

Unsere Prozesse sind präzise, effizient und entsprechen höchsten Qualitätsstandards – für eine sichere und verlässliche Messinfrastruktur.

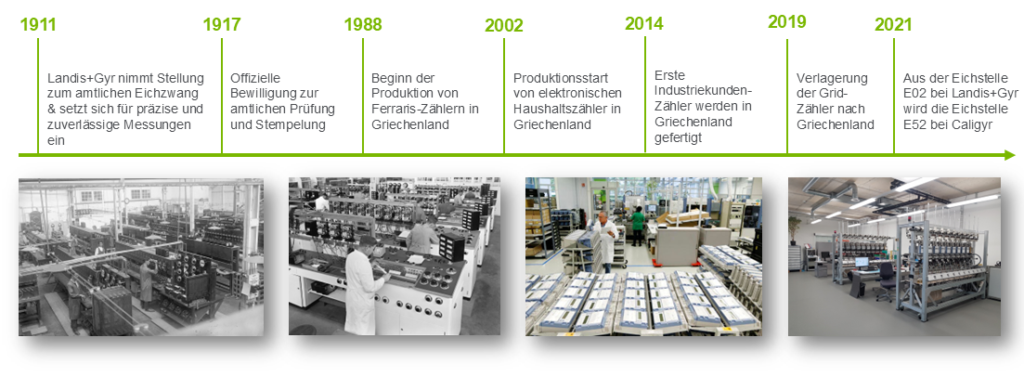

Geschichte von der Eichstelle

Mehr zu unserer Arbeit

Statistische Prüfverfahren

Das statistische Prüfverfahren, beschrieben in Anhang 4 der EMmV, ermöglicht eine effiziente Überprüfung der Messgenauigkeit von Stromzählern, ohne dass jeder einzelne Zähler ausgebaut werden muss. Stattdessen erfolgt die Prüfung anhand einer repräsentativen Stichprobe.

Ablauf des Prüfverfahrens

Bildung eines Loses:

Ein Los umfasst maximal 5000 Zähler desselben Typs und Herstellungsjahres.

Mehrere VerwenderInnen können gemeinsam in einem Los vertreten sein.

Jede VerwenderIn hat das Recht, zu erfahren, welche weiteren Beteiligten im gleichen Los sind.

Prüfung alle fünf Jahre:

Eine Stichprobe wird von einer durch METAS ermächtigten Eichstelle überprüft.

Besteht die Stichprobe die Prüfung, verlängert sich die Eichgültigkeit des gesamten Loses um fünf Jahre.

Falls die Stichprobe die Anforderungen der EMmV nicht erfüllt, müssen alle Zähler des Loses ausgetauscht werden.

Anmeldung zum Prüfverfahren:

Die Anmeldung zur Teilnahme muss bis Ende Juni des vierten Jahres nach Herstellung des Zählers bei einer Eichstelle erfolgen.

Dieses Verfahren gewährleistet eine kosteneffiziente Qualitätssicherung, ohne die gesamte Messinfrastruktur unnötig zu belasten. So bleibt die Genauigkeit und Verlässlichkeit der Strommessung langfristig gesichert.

Annahmeprüfung

Sicherheit und Präzision für Messgeräte

Die Qualität von Messgeräten ist entscheidend für genaue Abrechnungen, rechtliche Konformität und langfristige Zuverlässigkeit. Mit der Einführung der Europäischen Messgeräte-Richtlinie (MID) am 30. Oktober 2006 wurde das Zulassungs- und Eichsystem in den EU-Mitgliedsstaaten harmonisiert. Die MID regelt jedoch ausschliesslich das Inverkehrbringen von Messgeräten – nach dem Verkauf gilt weiterhin das nationale Eichrecht.

Ihre Verantwortung als Messgeräteverwender

Während die Hersteller für die Produktqualität verantwortlich sind, tragen auch Messgeräteverwender eine wesentliche Verantwortung für die Richtigkeit der Messwerte. Zwar kann man sich auf die Konformitätserklärung des Herstellers verlassen, doch eine zusätzliche Qualitätsannahmeprüfung bietet entscheidende Vorteile:

– Nachweis für die Produktqualität – Sie erhalten eine objektive Bestätigung, dass die Messgeräte den vereinbarten Standards entsprechen.

– Höhere Annahmewahrscheinlichkeit bei Stichprobenprüfungen – Eine geprüfte Qualität reduziert das Risiko späterer Ausfälle oder Abweichungen.

– Zusätzliche Sicherheit für Einkäufer – Eine QAP stellt sicher, dass die gelieferten Messgeräte den technischen und rechtlichen Anforderungen entsprechen.

Individuelle und massgeschneiderte Qualitätsprüfung

Die Qualitätsannahmeprüfung basiert auf einer klar definierten Vereinbarung zwischen Käufer und Lieferant. Dabei werden sowohl gesetzliche Vorgaben als auch individuelle Qualitätsanforderungen berücksichtigt. So erhalten Sie eine massgeschneiderte Prüfung, die genau auf Ihre Anforderungen abgestimmt ist.

Fazit: Eine Qualitätsannahmeprüfung schützt vor fehlerhaften Messwerten, minimiert Risiken und sorgt für maximale Transparenz – eine Investition in Sicherheit und Präzision.